There are endless arguments about whether condenser printing or diffusion printing is best. Most of my experience is with diffusion printing with various color enlargers and most recently with the Ilford 500 head on an Omega D5. I tried the condenser head on the Omega, but not enough to gain an appreciation for it.

The Durst 138S has an excellent set of condensers. With the new enlarger I got a full set of the T condensers (T indicates they are coated).

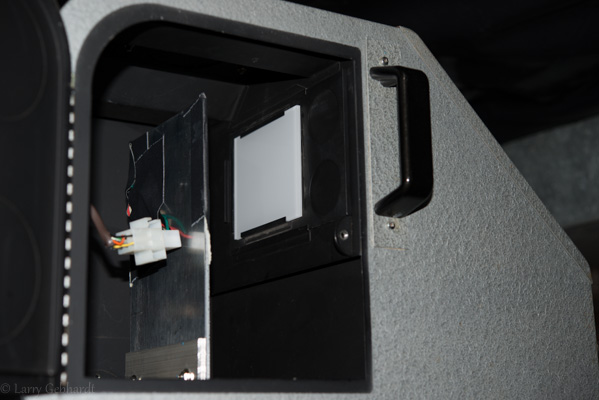

Three LED Light sources for the Durst 138S.

From the left 1) Variable Contrast diffusion, 2) Variable Contrast condenser, 3) point light

When I first got the Durst I didn’t have any choice but to print my 5×7 negatives with the condensers. I was able to get good results and found that the conventional wisdom on the subject is generally true. They really do print the same negative with more contrast. Prints do seem slightly sharper. The grain is better resolved. Scratches and dust on negatives is more apparent. But the conventional wisdom is wrong that a diffusion enlarger means you don’t need to spot as much. Diffusion still shows the dust, and it must still be taken care of.

The biggest issue I had with the condenser setup is that I can’t use pencil masking techniques. This is due to the fact the condenser setup relies on focusing an image of the light bulb at the nodal point of the lens. By adding an opaque mask above the negative you get some very uneven illumination since the condensers can no longer focus on the lens. Also, I lost the ability to finely adjust the contrast grade with VC papers, due to the use of VC filters only coming in 1/2 grade increments. This last part wasn’t much of an issue, but the loss of masking techniques was going to impact my printing.

So I built a diffusion light source for the enlarger, which is documented in a few posts. This is an LED diffusion head that has both green and blue LEDs for contrast control. This gave me the ability to print negatives with diffusion if I wanted to mask, but if I wanted the sharpness of the condensers I had to go back the old filtration control method with the hot tungsten bulb.

Another issue with the Durst 138S system is that it relies on large discontinued Opal bulbs. I have a few in various wattages now, and I found a PH/303 500watt bulb that works pretty well. The Opal bulbs are expensive and I doubt I’ll be able to find replacements as they get used up. The PH/303 runs pretty hot and requires a blower, which is a bit loud.

LED Condenser Light Source

I decided to build a head to get the advantages of the condensers along with the variable contrast control of the green and blue LEDs. I replaced the Opal bulb with a piece of milk glass that fits in the heat absorbing glass tray. Behind this I built an LED source with three green and three blue LEDs with the same specs as the ones used in the earlier head I built. I arranged these in a ring, alternating colors, on a piece of aluminum plate screwed to some aluminum angle iron. A few holes allow it to mount to the movable stage in the Durst head using the existing thumb screws. The plate also acts as heat sink. The LEDs were glued down with Arctic Alumina heat sink compound.

The Variable Contrast light source installed in the enlarger. Note the cable setup with a DIN plug mounted on the enlarger head wall and the quick connect plug on the light source.

Another view of the VC light source showing the opal glass installed in the heat absorbing glass holder. Milk plexiglass works just as well here.

I also installed a matching DIN connector in the body of the Durst light chamber so I can simply plug one of the cables used for the diffusion head into this and reuse my controller and the LED drivers.

I’ve only printed a few negatives with this system, but in testing it works very well. The light source is as even as the original bulb (corners are 1/4 of a stop dimmer than the center), and contrast control works as it should. Because of the efficiency of the condenser design it’s only a 2/3 stop slower than the diffusion head, even though it’s using 1/4 of the LEDs. I’m not sure what else I could ask for.

LED Point Light Source

The Durst has an optional point source lighting system, which I haven’t used or seen. It occurred to me that while I was messing around with LEDs that I could build one with a single LED, since they are very small (almost a perfect point) and very bright. I took a single CREE High Noon LED that I know gives a very good light for printing on VC paper with filters. I mounted this on a similar place of aluminum as I had for the other source.

This is used without the diffusion glass in the heat absorbing tray. The Durst system comes with controls to adjust the position of the bulb in three dimensions. Once I figured out how to position the LED I was able to get very even coverage over the whole frame. Every time you adjust the enlarger height you need to reposition the bulb. I now appreciate how well the Durst controls work for this.

So how does it work? Well you need to use contrast filters again since it’s a single white light. The single LED used as a point source is several stops brighter than the other light sources. It’s so bright I needed to add a neutral density filter under the lens. With a point source setup you need to use the lens wide open, so you can’t adjust the brightness using the aperture ring.

I printed the same image with grass that I used to try out the diffusion head. First print was very sharp, but odd looking. Took me a while to realize it was the pattern from the anti-newton glass in the negative holder. I removed the glass and made another print. This looked good. The point source is much sharper than the diffusion head and quite a bit more contrasty. It also shows every little flaw in the negative. There are a few odd areas that are on the negative and can be seen with a good loupe. These are barely perceptible on the diffusion print, but are almost glaring on printed with the point light source.

I don’t have enough prints made with this setup to know if I’ll keep using it. But I can see how it could be really interesting with some grainy 35mm film and large enlargements. Should be very sharp, and have clearly defined grain. I plan to experiment.

Conclusion

I now have three different options that all work well in the Durst 138S. I can use the same F/stop based controller for them all, and switching them takes only minutes. I can now choose the best lighting type for each image or printing situation.

What’s next? Well I may buy an LED star that has a green and blue LED in very close proximity. This might allow me to have a variable contrast point source. It’s possible thought that even a few mm offset would not align correctly. It will run about $20 to test that out. I also plan to spend more time making prints and less making enlarger parts.

I have done some LED enlarger conversions and am looking at what you have built with a great deal of interest. I had some problems with light fall off in the corners and like your idea of being able to dim the LEDs to fine tune the light. If I understand correctly you have 4 banks of 6 LEDs in your conversion each using one buck driver. I am wondering how you arranged the banks on the heat sink, I see an outer ring of 16 (8 blue and 8 green) and an inner ring of 8 (4 blue and 4 green) into the 4 sets of 6?

I am using an R H Designs F stop timer with an LED whiite light head and 12″x12″ vc filters. Your project has me inspired into working on a Green/Blue head with an Arduino control to set the paper grades. Thanks for sharing what you have done.

Bob

Hi Bob,

The LEDs are arranged in 4 banks as you state, each driven by one controller. Because I couldn’t get 8 LEDs on one driver dues to current issues I needed to compromise and the two short edges are all wired together, and the center and the middle of the long edges are wired together. So each bank has 6 LEDs of either blue or green.

I choose this compromise because with the 5×7 aspect ratio the middle of the short edges are slightly farther from the center than the middle of the long edges, so will have more falloff.

In practice I haven’t found it necessary to vary the brightness of the two banks relative to each other.

If you are building an 8×10 head you may want to increase the number of bulbs, which would require more controllers. This will give you more freedom to arrange them to account for the possibility of dimming.

My first LED head was white light as well. I never did get a 5×7 set of filters for that head. I think that would have cost more than the head did to build.

– Larry

Dear Larry,

I acquired a Laborator 138s a couple of weeks ago and recently stumbled upon your blog about the light source conversion. By now, you must have used the LED head quite extensively. Is there anything you would do differently? Maybe adding UV LEDs to get grade 5+ ?

I am planning to build a similar set-up and your posts are invaluable for my endeavor.

Thanks!

Karl

Karl, I’m glad to hear the posts are helpful. After using it for a while I don’t think there are many things I would do differently. My biggest complaint are mechanical. By now I had planned to rebuild the whole setup with a printed circuit board and a better case. So the issues I have are the power supply box has a few light leaks from the internal LEDs, the cable I made to connect the power supply with the LED drivers and the head is too short and nor flexible enough. Also I wish I had used internal connectors so I could plug the light box in without needing to move the cables around. But I’ll get to all that later.

I’ve also changed the programming a few times to better handle split grade printing and test strips. I also added support for reading paper curves off of the SD card. This allows me to have bright curve for large prints (and my old Forte Polywarmtone paper), and a dim curve for smaller prints. That’s one thing I really like – adding new features without any hardware changes.

I don’t think UV LEDs would get us more contrast, but I haven’t tested it. But either way I rarely, if ever, need more contrast. And if I do I find it’s better to intensify the negative and use lower contrast light.

Let me know when you get your head built. I’m always interested in what people are building.

I’m looking at doing this for my Omega D5500. Regarding the LED arrangement – was it experimentation that determined where the LEDs were place, or something more scientific?

I measured the distance from the LEDs to the diffusion screen. From there I could calculate the intensity of any one LED based on the falloff curve published by the manufacturer. I started writing a program to figure out the optimal placement, but never finished it. What I did to get it done quickly was create a radial gradient based off the falloff curve in Photoshop. I then blended the gradients and moved the 12 LEDs around as separate layers until the distribution was as even as I could make it.

The one area I’m not completely happy with is the spacing between the green and the blue. Ideally both LEDs would be on one die very close to each other. You can get them custom made with three LEDs on one star. I’ve got a few to play with containing red, green and blue on the same star.

Hi,

I will soon have a darkroom and will print with a Durst M800 and multicolor head. Do you have any recommendation for “testing” the paper grade and how to do it properly? Once I have a decent workflow and possibly a bigger room I’ll embark in some mod for the enlarger.

alberto, It’s a bit much to get into in a comment, but you will want to get a step wedge (21 step is fine http://www.stouffer.net/TransPage.htm) and a densitometer. From there print the wedge to paper with different filtrations. Plot the curves and you can read from them to calculate the grade. I tend to ignore the standard 00-5 grades and stick to the ISO grades which correspond to the negative range (basically negative density range x 100). See http://www.ilfordphoto.com/Webfiles/2006130200232336.pdf in the ISO range section.

Hello Larry!

I found your blog about making the led head for Durst 138. It inspired me, so I made somethink similar for my Meopta Magnifax. Some time ago I made Brodie Tyrrell FStop timer too. I have reading about your remaking for control to led head with using Arduino mega. I am interested how worked it? Are these two alone units (first for control of led head and second for control of fstop timer) in one Arduino mega? Or is it control of contrast (control of led head) integrated with function of fstop timer?

Best regards

Raduto

Raduto,

The Arduino Mega based controller works well. It controls both the contrast and the time (f-stop based) with one controller. Contrast is variable by independently adjusting the green and blue exposure.

How does your new head work?

Larry

Larry,

The head is phase of testing. I am looking for the ideal material for difuser. I have using five green 3W led and five royal blue 3W led (mid format 6×6 cm). I am controlling it by two 700mA PWM drivers and Arduino uno.

To your Arduino mega controller: I am interesting in adjusting of the contrast. Is contrast setting directly in function of Brodie Tyrrell timer (strip test and exposure steps)? For example: Strip test – Base 2EV/step 0.5EV/grade 3 or Exposure steps – Base exposure 2EV/grade 4, Burn sky 1EV/grade 2, Dodge face 1EV/grade 3 … etc. Or if you have control of brodie tyrrell fstop timer and led head contrast controller separately.

Can you show me some documentation please?

I am sorry for my English. It is not good.

Raduto

Raduto,

See http://www.trippingthroughthedark.com/variable-contrast-led-head-for-durst-138s-progress/, specifically the link to the github repo where I store the code https://github.com/lgebhardt/led_fstop_timer. I haven’t updated it in quite some time, but it still works. It’s based on William Brodie-Tyrrell’s F/Stop timer so it should be familiar to you. It still allows multiple steps for dodging and burning, and the contrast is adjustable for each step so you can burn the sky in at a lower contrast for example. Unfortunately I haven’t written up documentation, but it should be relatively close to the the original F/Stop timer with the additional contrast steps. The addition of papers and an SD card reader is the newest/biggest change to the code, but I built a curve in for Ilford MG IV, so it should be useable out of the box. If you build a copy I’ll be glad to help you get setup making your own custom paper profiles.

I used thin opaque plexiglass which works OK. I’ve tested Makrolon LD and it seems to be a bit more even, at the expense of a bit of brightness.

Larry

Larry,

I would like to making your version of Fstop timer with cotrolling led, because i want everything all in one.

I downloaded files from GitHub and did simulate to watching how worked it. Function of Fstop timer is the same like original Brodie Tyrrell but I don´t understand completely to addition functions for controlling of contrast.

Can you write me informations about functions please?

(_redacted_@gmail.com)

Thanks for your help, Raduto

Raduto, I’ll try to write up some decent instructions soon. First build using the split_grade branch (I still need to merge it). Note that the new code requires a 4×20 display instead of the 2×16 display of William Brodie-Tyrrell’s F/Stop timer. If you have that and it’s running you should see a few new things on the screen. The grade is displayed in ISO units, so 100 is about equivalent to grade 2, and every 20 units moves up about a paper grade in the ASA units (so 120 is roughly grade 1 and 80 is roughly grade 3). The H indicates Hard light (blue) and S is for soft (green). To change the grade for a step press 9 (as indicated on the last line), enter the new grade and Press B. You can set the grade for each step. Note there is a weird glitch where sometimes the grade doesn’t store. If that happens renenter the exposure and then the grade should be accepted (I’ll try to fix that).

Each step can use it’s own grade. In addition you can toggle just the hard or soft light for a step while editing by pressing * (H) or 0 (S). That way split grade exposures can be performed. When exposing it will show the % power to each bulb color.

I hope that’s enough to get you started. The calibration of papers will take me a while to write up.

Larry

Hi Larry

If you found time to write some instructions to Raduto, I would be very thankful for a copy. I have built the two versions of the William’s f-stop timer and are quite happy with them on my Durst 138 with colorhead. Just recently got myself a Focomat Iic without multigrade filter and since buying the large multigrade filters would set me back around 100 USD, why not use the opportunity to try out LED and get a more friendly solution than mechanical changing filters.. and then play with the options of integrating it with the f-stop timer. Now if you have done the hard work even better :-))

Any updated schematics? I hope to use motor controllers for the PWM controls of the LEDs as opposed to the power controller you used, in order to achieve the quick on/off and full scale dimming, but there might be a reason I’m not aware of for using the controllers you selected??

Best regards

Morten

Hi Morten,

I haven’t had time to write up more detailed instructions yet. I’ll be sure to send you a copy when I do.

I don’t have updated schematics, again I’ve been short on time. I’m not sure what you mean by motor controllers. As long as you can use them to control the current going through the LEDs with a PWM source they should work. When I was last working on the project I was testing out some Meanwell LDD-700H drivers mounted on a simple board, but it should be simple to make your own. They take direct PWM inputs and can output up to 52V, which should drive more than 12 LEDs in a chain. I was going to provide the PWM signals from a multichannel 12bit PWM I2C chip (like PCA9685) to keep the wiring simple and get a bit more precision than the arduino mega’s PWM outputs provide (8 bit without resorting to hacks). I’m at the stage where I’ve got all the parts but haven’t started assembly.

Larry

Hi Larry,

Thanks! No rush, I’m more at the idea stage with bits in the mail from eBay.. And then summer is coming, I rather would be out shooting! I need to work more on the design, will send you an update once I have a draft design / schematic. Depending on how linear the paper response is I think 8 bit PWM for each channel should be sufficient, but prototyping will tell!

Pingback: Arduino and Photography - Gavin Lyons Photography

Hi Larry, I’m trying to compile the Github code (split grade branch) however no luck. Looks for and are unable to find the file “TSL2561.h”. Any hints?

Best Regards

Morten

You can comment out any of the TSL2561 code. It isn’t being used. Sorry for the confusion caused by accidentally committing it.